NIVEA Shower Gel Refill Station

The new reuse experience

NIVEA Shower Gel Refill Station

Beiersdorf AG

Fast Company - 2021 Innovation by Design Award - Honoree - Retail Innovation

Deutscher Nachhaltigkeitspreis 2022 (The National German Sustainability Award) - Finalist - Design

ADF Innovation Awards 2021 - Winner - Industrial and Technical Innovations

Designboom - TOP 10 Social Impact Stories 2020

MUSE Design Award 2020 - Gold Winner - Packaging Design

Packaging Europe - The Sustainability Awards 2020 - Winner - Reader's Award

Role: Design Lead, Service Design, Interaction Design, Design Research, Qualitative Study (Focus Groups), Quantitative Study, Technical Brief & Patent, Concept Development, Design Management | Patent (pending)

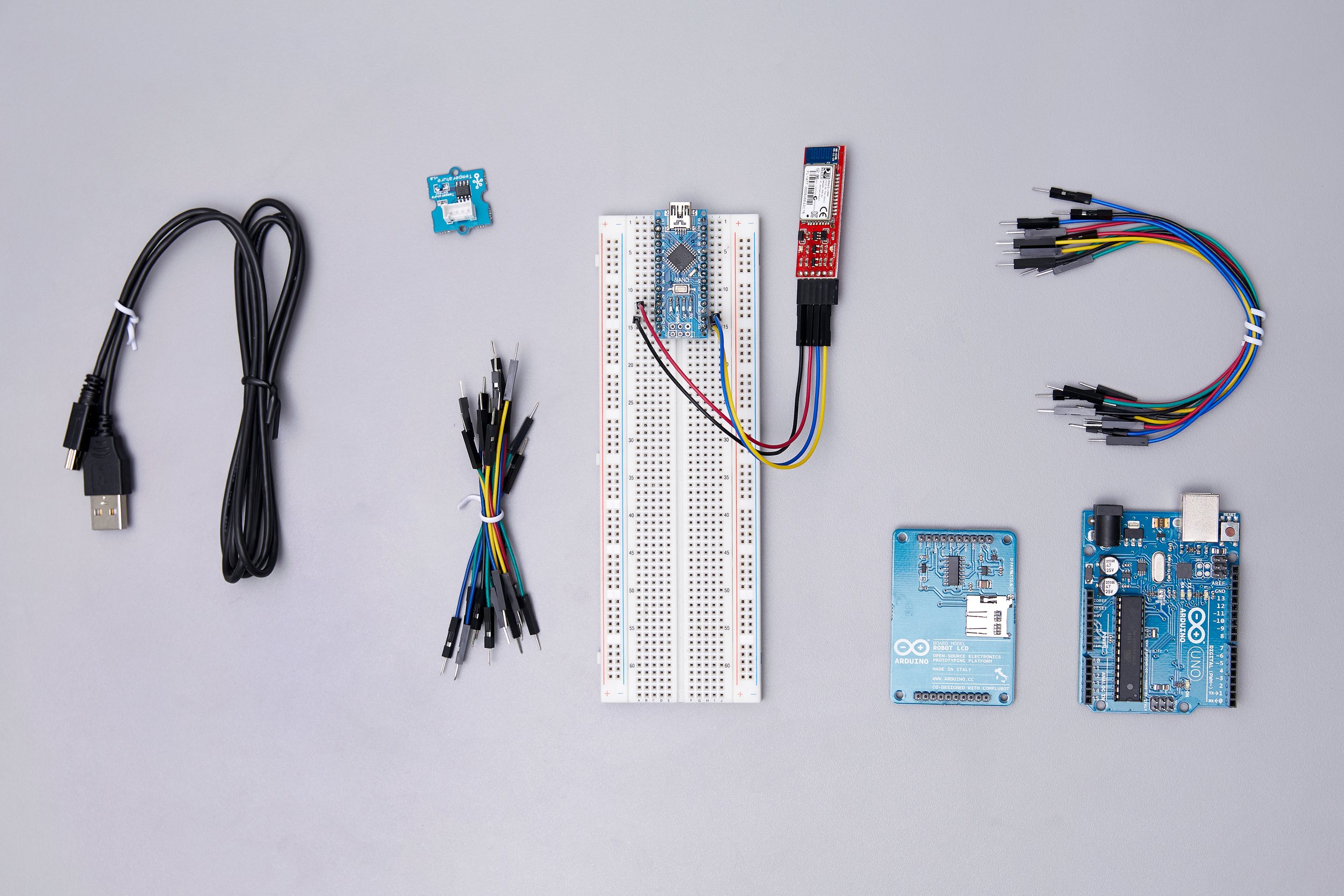

Tool: Arduino, SolidWorks, 3D Printing, Laser Cutting, Adobe Illustrator, Adobe Photoshop, Sketching

External Partner: Unison Design & Engineering Hamburg (Robert Roediger, Maximilian Krug): Design Engineering, Industrial Design, Coding

Images and text shown on this page are ownership of Beiersdorf AG

Refill instead of throwing away

– that’s the idea behind the first refill station for NIVEA shower gels

Inclusive interview for designboom:

German skincare manufacturer beiersdorf is on a mission to minimize, slow down, reduce, and close its material cycles. with a focus on plastic packaging, beiersdorf’s biggest global brand, NIVEA, has just launched its first shower gel refill station. the prototype, which will be in select DM stores in hamburg and ettlingen, will investigate the concept of reusable bottles with consumers. the machine has been designed, developed, and engineered by a cross-functional team within beiersdorf’s global packaging and R&D functions.

‘first, we had to understand and define the consumer and shopper experience to design a holistic solution’ says caroline zia, senior formula developer at beiersdorf. ‘while the concept of refilling is not entirely new, the personal care category does not boast widespread use of this technology yet. we had to identify the best possible scenario for the consumer and for sustainability. not all formulations are suitable for such a concept. the formulations need to withstand the additional burden of refilling and we had to carefully choose our products after extensive internal testing. also the machine had to be programmed for additional cleaning protocols. this way we could guarantee multiple filling loops and still meet our safety and sustainability criteria,’ she says.

referring to the design execution of the machine, marta suslow, concept designer at beiersdorf’s packaging department, adds: ‘as the next step, the industrial design of the machine had to be sketched out. here we successfully outlined possible routes and fine tuned the winning concept according to the retailer’s interior requirements. our main intention was to create a distinctive and easy user experience. therefore, for example, we decided to use light as a visual support to guide the users. whenever one of the dedicated refill-bottles has been filled or a bar code has been printed, the integrated LED lights give feedback to the consumer. beyond the 3D design itself the machine also had to be engineered.’

bernhard felten, beiersdorf’s packaging prototyping expert explains further: ‘due to restricted time and budget, we realized the minimum viable product and left out a lot of features we originally had in mind. still we use a scale to control filling, a QR/bar code reader to handle the batch coding, formula choice and refill cycles, as well as sophisticated pumps, color changing lights, a label printer and a programmed micro controller to ensure we integrate all required functions in an aluminium structure covered with powder coated steel sheets. the lean concept end result, which we managed to get CE certified, will provide an easy and safe refill experience to our consumers.’

‘I am especially excited about the fact that we made the step from prototyping to additive manufacturing with our in-house 3D printers’ comments felten. suslow emphasizes an additional sustainability aspect: ‘with regard to sustainability we decided to use recycled PET for our refill-bottles. therefore, the consumer will not only experience the idea of reusability when participating in our pilot project but will also be part of a recycling loop, as we will recycle the returned bottles again after the test phase’.

the test phase of this pilot project will take place over six to eight months in selected DM stores in hamburg and ettlingen. the aim is to learn about the consumer acceptance and gain knowledge about the usability and supply chain handling. koushik sreedhar, who has been involved in the project as the lab manager summarizes: ‘we are looking forward to receiving as much feedback as possible on the design, functionality and sustainable brand experience and hope for a high consumer involvement.’

Images: Beiersdorf AG